E350

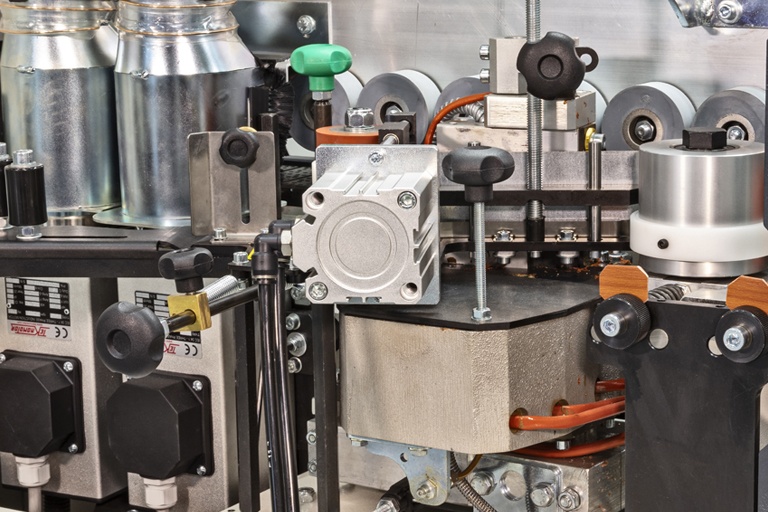

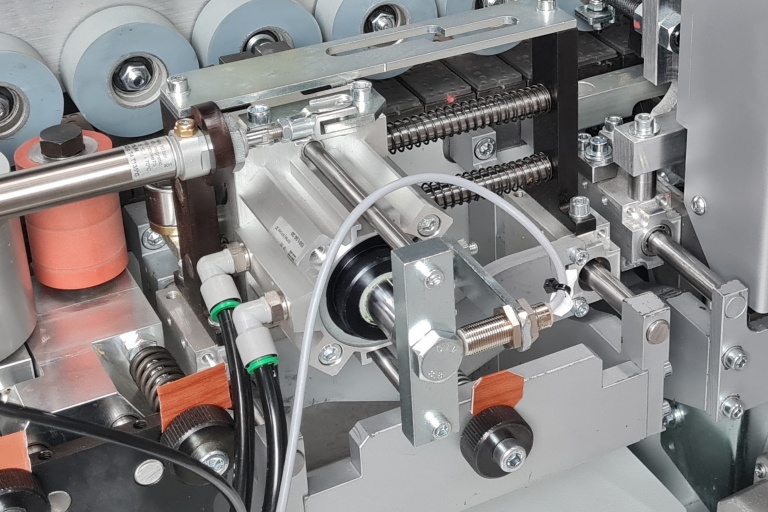

Automatic edge bander with hot melt (EVA) glue pot with chain panel feeding

Automatic edge bander with hot melt (EVA) glue pot with chain panel feeding

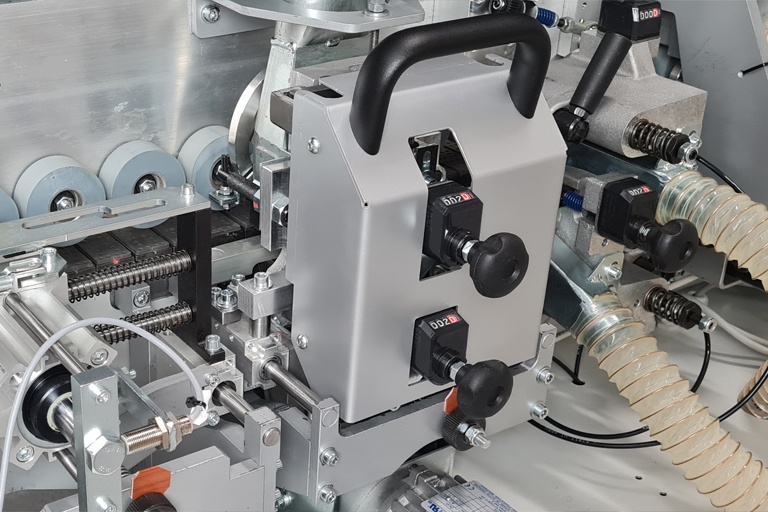

DETAILS THAT MAKE THE DIFFERENCE

PERFORMANCE AND VERSATILITY

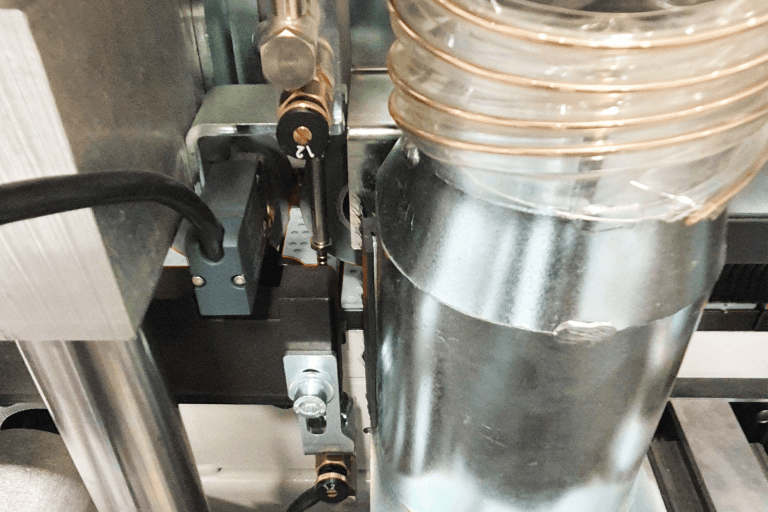

INSTANT PERFECT CLEANING

TO GUARANTEE THE BEST GLUEING CONDITIONS